From Factory Floor to Classroom: The New Wave of Industrial Educational Robots

The Dawn of a New Era in STEM Education

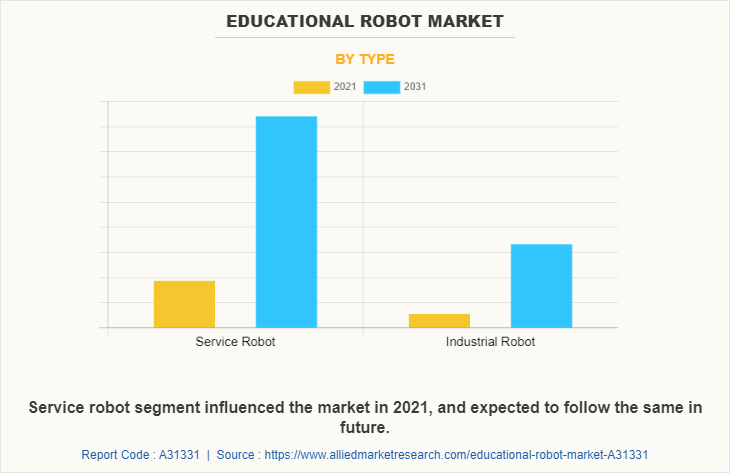

For decades, the landscape of educational robotics has been dominated by colorful building blocks, programmable kits, and introductory coding toys. While invaluable for sparking initial interest in science, technology, engineering, and mathematics (STEM), these tools often stop short of preparing students for the complex realities of modern industry. However, a significant transformation is underway. The latest Educational Robot News reveals a powerful trend: leading industrial robotics manufacturers are now designing and releasing scaled-down, classroom-safe versions of their sophisticated factory-floor machines. This strategic shift is not merely an update to existing product lines; it represents a fundamental change in how we approach vocational and technical training. By placing authentic, industry-grade technology directly into the hands of learners, these platforms are bridging the critical gap between academic theory and real-world application, democratizing access to skills that are in high demand across the global economy. This evolution marks a departure from the trends seen in Smart Toy News, moving beyond entertainment and into genuine career preparation.

Section 1: The Evolution from Playful Bots to Professional Trainers

The journey of educational robotics is a fascinating story of increasing sophistication and purpose. Understanding this evolution helps contextualize the profound impact of introducing industrial-grade systems into learning environments. It’s a narrative that moves from basic programming concepts to the complex, integrated systems that power modern automation.

From Block-Based Coding to Authentic Industrial Languages

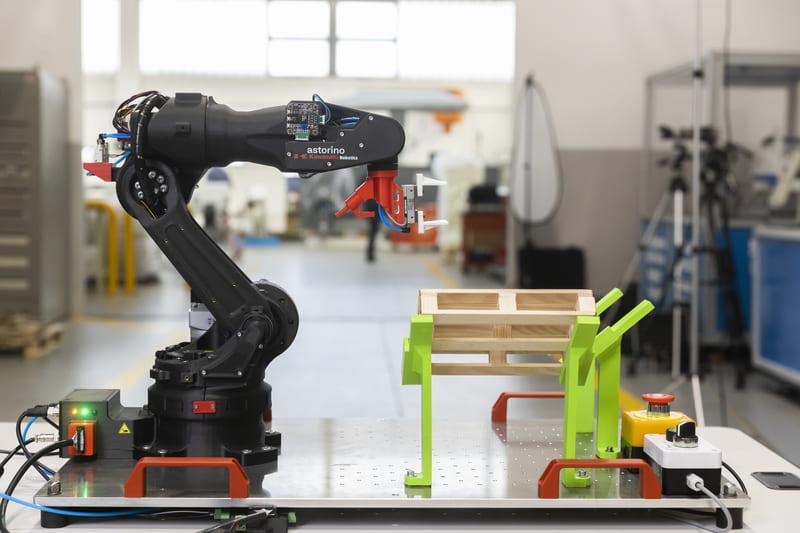

The first wave of educational robotics, largely driven by platforms like LEGO Mindstorms, revolutionized STEM learning by making abstract concepts tangible. The latest Robot Kit News and Coding Toy News continue to highlight the value of these systems for teaching foundational logic and problem-solving. Students could build a robot and use simple, block-based visual programming to make it move, react to sensors, or complete simple tasks. This approach lowered the barrier to entry, making programming accessible to younger audiences. However, the programming languages and mechanical principles were often simplified abstractions of professional tools. In contrast, the new generation of educational robots from industrial giants offers a no-compromise experience. Students don’t just learn “coding”; they learn the specific, text-based programming languages (like Python, C++, or proprietary languages like Kawasaki’s AS) used to control millions of robots in factories worldwide. They interact with professional-grade teach pendants—the same handheld controllers used by robotics engineers on the assembly line—to manipulate the arm and set waypoints, providing invaluable muscle memory and procedural knowledge.

Key Characteristics of the Modern Educational Robot

These new tools are defined by a trio of core principles: authenticity, safety, and accessibility. Authenticity means they are not toys but true robotic systems, often featuring 6-axis articulated arms capable of complex movements, with specifications for payload and reach that mirror their larger cousins. Safety is paramount; they are engineered with features like force-limiting sensors, reduced speed modes, and lightweight construction, allowing them to operate safely alongside students in a classroom setting—a key topic in AI Toy Safety News. Finally, accessibility is achieved through a combination of reduced cost (a fraction of a full-scale industrial robot) and a comprehensive support ecosystem. This often includes simulation software, detailed curricula, and online resources, which are frequently discussed in AI Toy Community News and AI Toy Tutorials News, ensuring educators can effectively integrate them into their lesson plans.

Section 2: Anatomy of a Classroom-Ready Industrial Robot

To appreciate the educational power of these new robotic systems, it’s essential to look under the hood at both their physical hardware and the sophisticated software that drives them. This is where the distinction between a simple programmable toy and a professional training tool becomes crystal clear. Unlike the singular focus of a product featured in AI Drone Toy News or AI Vehicle Toy News, these robots are designed for versatile, multi-disciplinary applications.

Hardware: Precision Mechanics and Sensory Input

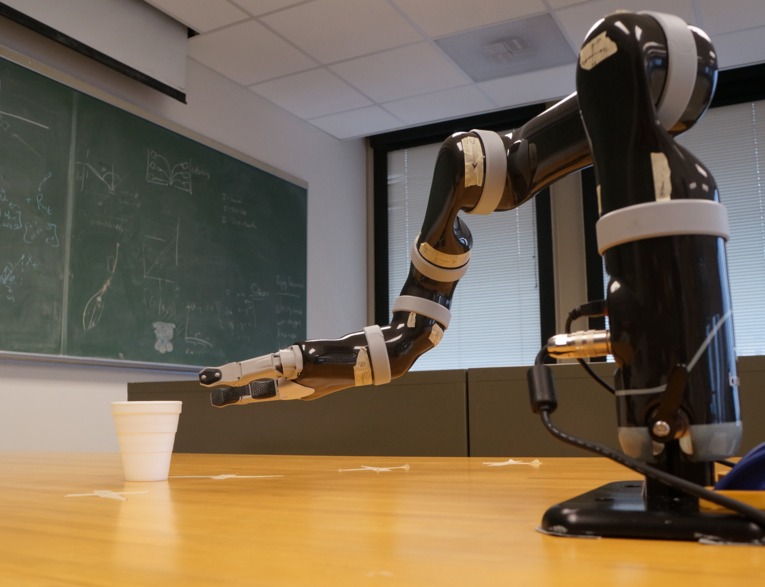

The core of these systems is typically a 6-axis (or 6 Degrees of Freedom) robotic arm. This design is the industry standard because it allows the robot’s end-effector to achieve any position and orientation within its workspace, mimicking the dexterity of a human arm. This is crucial for simulating real-world tasks like welding, painting, material handling, and intricate assembly.

- End-of-Arm Tooling (EOAT): A key feature is the ability to swap out the “hand” of the robot. Students can experiment with pneumatic grippers, vacuum suction cups, welding tools, or even 3D printer extruders. This modularity, a hot topic in Modular Robot Toy News, teaches the critical concept of systems integration and is a frequent subject of AI Toy Accessories News. Some programs even encourage students to design and 3D print their own custom tools, linking directly to trends in Toy Factory / 3D Print AI News.

- Sensors and Vision Systems: Many educational models can be equipped with advanced vision systems and sensors. This elevates the learning from simple pre-programmed paths to dynamic, responsive automation. As highlighted in AI Toy Sensors News, students can program the robot to identify objects by color or shape, perform quality control inspections, or adjust its actions based on real-time environmental feedback—skills that are indispensable in modern manufacturing.

Software: The Digital Twin and Programming Interface

The software ecosystem is arguably as important as the physical robot. The best platforms offer a dual-pronged approach to learning. For beginners, a simplified, drag-and-drop interface might be available, easing the transition from the block-based environments seen in Programmable Toy News. However, the ultimate goal is to move students to the professional, text-based programming environment. A central component of this ecosystem is the “digital twin”—a highly realistic simulation software that creates a virtual replica of the physical robot and its work cell. Students can program, test, and debug their automation sequences in this safe, virtual space before deploying them to the real hardware. This workflow not only prevents costly mistakes and damage but is the standard operating procedure in the industry, making it an essential skill for aspiring engineers and technicians. The seamless connection between software and hardware, a key area of focus in AI Toy App Integration News, is what makes this training so effective.

Section 3: Bridging the Skills Gap and Fostering Innovation

The introduction of industrial-grade educational robots is a direct response to a growing skills gap in the manufacturing and technology sectors. By providing hands-on experience with the exact tools used in the industry, these platforms are creating a direct pipeline of talent, while also unlocking new avenues for creativity and cross-disciplinary collaboration.

Real-World Scenario: A High School Automation Project

Imagine a vocational high school class tasked with automating a small assembly line. Using an educational robotic arm, students don’t just write a few lines of code. They engage in a holistic engineering project. They must first analyze the task, design the workflow, and select the appropriate end-of-arm tooling. Using the simulation software, they program the robot’s movements, optimizing for speed and efficiency (cycle time). They integrate external sensors to detect when a part is in place and a simple conveyor belt to move products. Finally, they deploy the program to the physical robot, troubleshoot errors, and refine the process. In doing so, they learn about industrial controls, systems integration, project management, and quality assurance. This hands-on, project-based learning is far more impactful than textbook theory and is a prime example of the latest trends in AI Learning Toy News.

Beyond Manufacturing: Cross-Disciplinary Applications

While the primary application is in manufacturing and engineering, the versatility of these robots opens up exciting possibilities across other fields. This contrasts with more specialized products seen in AI Musical Toy News or AI Sports Toy News.

- Art and Design: Students can program robots to paint, draw, or sculpt, exploring the intersection of code and creativity. This is a practical application of concepts often discussed in AI Art Toy News and AI Drawing Toy News.

- Healthcare and Lab Sciences: The precision of these arms makes them ideal for simulating tasks like sample handling, liquid dispensing, or even mock surgical procedures, providing a safe way to train future lab technicians and medical professionals.

- University Research: For universities, these affordable platforms are a boon for research in human-robot interaction, machine learning, and computer vision. They provide a reliable hardware base for testing new algorithms, a key driver of AI Toy Research News.

The curriculum must also address the societal implications, a topic central to AI Toy Ethics News, ensuring students understand the impact of automation on the workforce.

Section 4: Recommendations for Educators and Institutions

Adopting this new technology requires careful consideration. For educational institutions looking to invest, it’s not just about buying a piece of hardware; it’s about investing in a comprehensive learning platform. The decision-making process should be guided by curriculum goals, scalability, and long-term support.

Pros and Cons of Adoption

Pros:

- Career-Readiness: Provides students with immediately applicable, in-demand job skills.

- High Engagement: The “wow factor” of controlling a real industrial robot is a powerful motivator for students.

- Versatility: A single robot can be used across multiple disciplines, from engineering to art.

- Future-Proofing: Aligns educational programs with the direction of Industry 4.0 and smart manufacturing.

Cons:

- Higher Initial Cost: Significantly more expensive than traditional robot kits or a simple AI Plushie Companion News item.

- Steeper Learning Curve: Requires more instructor training and a more structured curriculum.

- Space and Infrastructure: Requires a dedicated, safe space for operation.

- Maintenance: As professional equipment, it may require more specialized maintenance than a consumer toy.

Key Considerations for Selection

When evaluating different options from various AI Toy Brand News sources, educators should look beyond the spec sheet. How robust is the curriculum provided? Is there an active user community for support, as highlighted in AI Toy Tutorials News and AI Toy Reviews News? Does the platform scale, allowing students to progress from basic pick-and-place operations to complex, sensor-driven tasks? Answering these questions is crucial for ensuring the investment translates into meaningful learning outcomes and represents a true step forward in educational technology, a constant theme in AI Toy Innovation News.

Conclusion: Building the Future, One Robot at a Time

The emergence of affordable, classroom-ready industrial robots marks a pivotal moment in STEM education. These are not mere toys; they are powerful training instruments that demystify the world of automation and provide a tangible link between learning and career. By moving beyond simplified abstractions and embracing authentic, industry-standard technology, educators can empower the next generation of engineers, technicians, and innovators with the skills they need to thrive in an increasingly automated world. The latest Educational Robot News is clear: the factory of the future is being built today, and its foundations are being laid not just on the assembly line, but in the classroom. This trend is the most significant development in the STEM Toy News space, promising to shape the workforce for decades to come.